PRODUCTS

BARBED RAZOR WIRE making MACHINE AKL-300

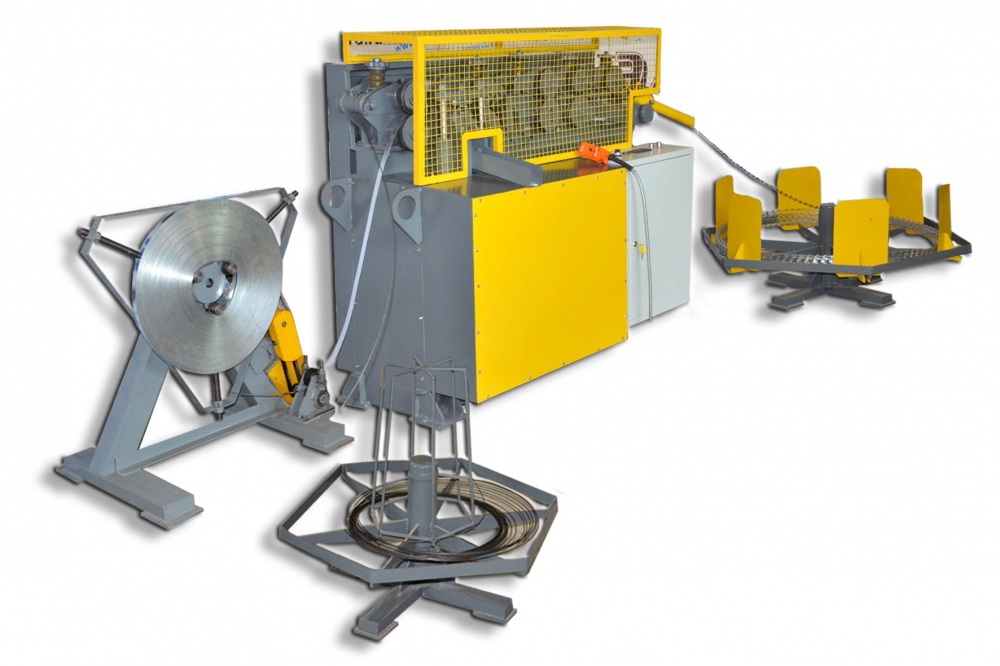

Automated line AKL-300 represents a high-speed punching press fitted with a folding unit and automatic piler and intended for Egoza barbed wire making.

Commercial offerBrief description:

Auto mode

Capacity: 10.82m/min

Power consumption: 5.5kW/380V

Warranty: 1 year

Scope of supply:

AKL-300 machine

For proper work, the automated line requires one operator only. A finished reinforced barbed tape Egoza is wound into a take-up carrousel.

The resulting coil diameters are 500mm to 1200mm. Diameter can be changed in 5 minutes as maximum by moving the carrousel blades closer to/further from the center.

The machine will stop after the set metreage is achieved. Operator will need only to fasten together the tape turns in three or five points depending on the final consumer diameters and requirements. The turns are manually fastened using special-purpose tongs or a special pneumatic crimping tool.

Fully integrated production of the reinforced barbed tape Egoza requires indoor space of approximately 50 m2 where a machine, raw materials and finished products storage can be arranged.

A small workbench is also needed to produce mounting brackets for spiral fencing.

Due to low power consumption the manufacturing process can be launched even in a garage. The only requirement is 3-phase 380V supply.

The equipment has a warranty period of 12 months.

Includes punching and forming unit. Automatic operating mode. 330 conventional strokes per minute. Crimped tape output from 3х m/min in a tape feeding mode and up to 10 m/min in an operating mode. Output width of the RBT (reinforced barbed tape) is 12 mm. Power supply – 380V. Available HP - 6 kW as maximum.

Galvanized strip feed

Galvanized strip features – Width 20mm, Thickness - 0.4-0.55 mm, of steel as per GOST 14637, galvanized as per GOST R52246-2004 or galvanized polymer-coated as per GOST R52146-2003. Maximum coil diameter is up to 1200mm.

Pay-off stand

Wire 2.5mm. Also a wire as per GOST 9389-75, GOST 3272-74, and GOST 7372-79 can be applied. Maximum coil diameter is up to 1200mm. Coil height – up to 400mm. Coil weight – up to 200kg.

Finished reinforced tape reel with automatic piler

(w/o crimping mechanism)

Operates in automatic mode. Finished products are stowed into carrousel. A spool can be replaced with a metal one. Spool diameter is 500 to 1200mm. Not included in the scope of supply.

All the required technical documentation and certificates

Equipment Technical Data Sheet, Warranty Certificate, Certificate of Conformance with GOST R, accounting records.

Customer's employees training

Two-day training of up to 3 Customer's employees at the Service Provider's production site. Travel costs, accomodation costs and meals shall be borne by the Customer.

Loading to the Customer's transport

Top loading to the Customer's motor transport